Project Description

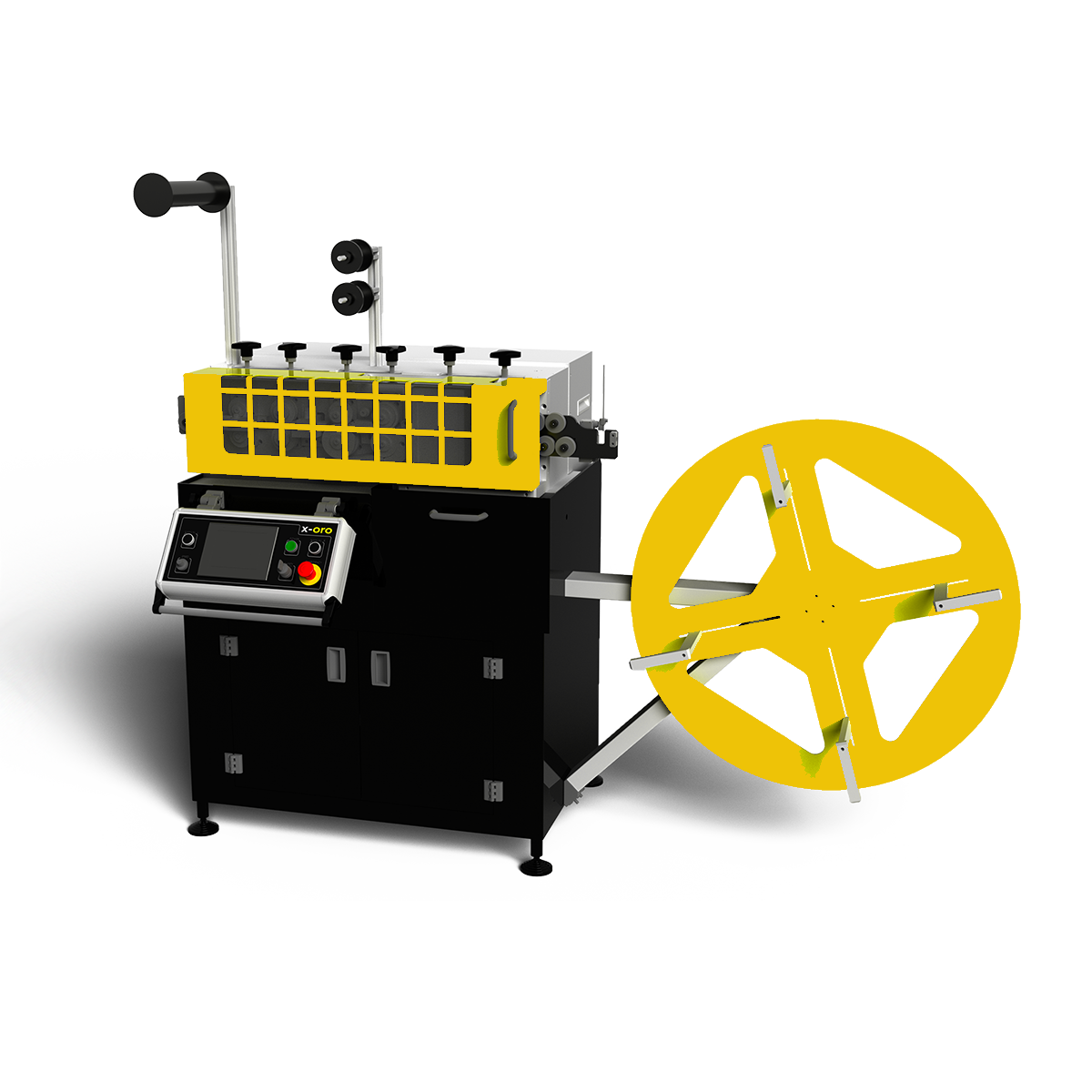

HOLLOW WIRE MACHINE WITH ROLLING SYSTEM – IR05

HOLLOW WIRE MACHINE WITH ROLLING SYSTEM – IR05

Automatic machine for the production of crimped wire, for the production of hand-made or machine-made hollow chains, in gold, platinum or silver.

On the right side of the machine there is an unwinding reel, where the skein of Ø 5 mm round wire called “core” is loaded, which can be made of tombak, copper or iron. This “core” constitutes the internal part of the seamed/crimped product, which will be finally removed through the “emptying” process.

By means of the dragging driving rollers this “core” is driven onto the wire-straightening unit, in order to make it perfectly linear; The milling unit is located immediately nearby and it consists of 4 rolls that carry out 2 upper and 1 lower channels/grooves on the wire, which will be used for the subsequent seaming/crimping of the slab.

At the same time, on the other side of the machine, the gold, platinum or silver plate is shaped through a train of wheels/rolls, so as to wrap it around the “core” profile, blocking onto the 2 previously formed channels/grooves.

Always at the same time, depending on the need, it is possible to automatically insert 2 welding wires inside the two upper channels/grooves and 1 welding wire inside the lower channel/groove, which will be used in the end to weld the chain through another manufacturing process.

Finally, a pulley block / roll frame makes the profile square, keeping the line perfectly in its position so as to ensure that the product is not damaged during the subsequent “rolling” phase.

The final result is a perfectly compact crimped wire, between a gold / silver plate and a tombak / copper or iron core; square shaped, with the possibility to have two or more welding wires inside it, ready for subsequent manufacturing processes.

This crimping system has the advantage of carrying out the production of hollow wire, by simply inserting on the machine a wire called the “core” as well as the plate to be crimped, without any loss or metal scraps/waste.

The machine is equipped with an LCD touch color control panel and a Speed regulator, and it is already set up for INDUSTRY 4.0.

Machinable dimensions and equipment

| Wire (“core”) | Ø 5 mm in tombak, cooper or iron |

|---|---|

| Sheet thickness | 0,15 – 0,80 mm |

| Rolling Heads | 2 |

| Profiling Heads | 4 |

| Welding | possibility to insert 1, 2 or 3 welding |

| Productivity | 1,5 m/min |

Technical features

| Power | Ø 5 mm in tombak, cooper or iron |

|---|---|

| Power supply | 0,15 – 0,80 mm |

| Machine dimensions | 240 x 80 x h.170 cm |

| Weight | 550 Kg |