Project Description

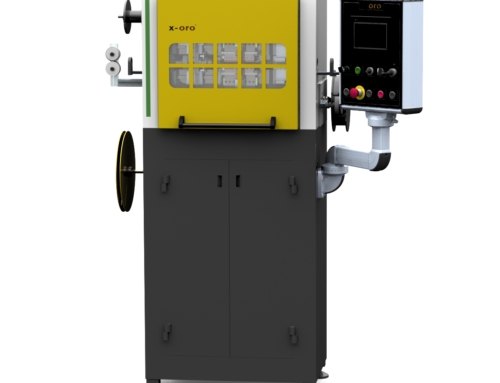

CNC-controlled machine for the diamond cutting process of spherical balls/beads, or of different specially shaped balls.

CNC-controlled machine for the diamond cutting process of spherical balls/beads, or of different specially shaped balls.

The balls/beads are placed onto a vibrator. The action of the vibrator pushes the balls onto special guiding devices, leading them to the loading position. A special gripper takes the balls and positions them onto the motorized tailstocks, blocking them through the holes.

The diamond cutting unit performs the processing of the ball/bead, by diamond cutting it according to the design to be manufactured, thanks to the CNC-system, which through the ISO programming system manages its 9 control axes, 4 of which are linear ones and 5 rotational ones, by carrying out interpolated movements of the diamond-cutting unit with the tailstocks unit, making it possible to carry out the diamond cutting process of spherical balls/beads or of balls with special and complex geometrical shapes.

The diamond-cutting process takes place inside the cab, so as to guarantee easy recovery of metal waste/scraps.

This machine has already been set up for IND.4.0; on request it can be set up for remote customer care assistance.

| Control unit | 9 axis CNC |

|---|---|

| Tool rotation speed | 18000 rpm |

| Tool size | standard size Ø 100 mm – Ø 80 mm can be suppied on request |

| Power | 3 KW |

| Power supply | 230 V – 50/60 Hz |

| Pneumatic feeding unit | 6 bar |

| Machine weight | 850 Kg |

| External dimensions | 180 x 100 x h.190 cm |