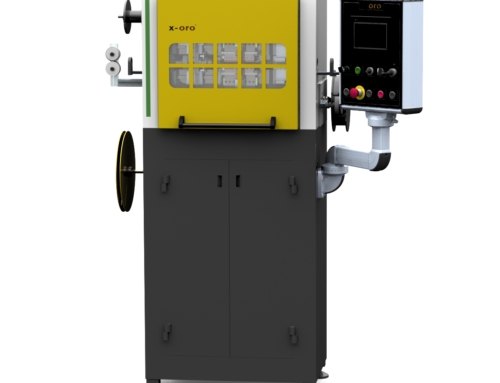

Project Description

Automatic machine for the production of earring studs/pins, which can be either Rolled, with special shape or Threaded; they can be in precious as well as non-precious alloys.

The wire is inserted into the machine and straightened by means of being driven through a special wire-straightening unit.

Subsequently the machine carries out the rolling or threading process according to the mounted equipment/tool, while wire trimming is adjusted according to the set length.

The machine is equipped with a stamping unit so that, in case it is desired, it is possible to insert both stamp and company logo.

Machining processes of this machine do Not imply the production of waste/scraps or scraps of the processed material.

Speed adjustment as well as the quantity of pieces to be produced, can be set on the PLC display.

| Working Dimensions | wire min. Ø 0.50 – max. Ø 1.50 |

|---|---|

| Pin lebngth | min. 8 mm – max. 20 mm |

| Production | 45 – 55 pcs/min |

| Power supply | 220 V – 50/60 Hz |

| Pneumatic supply | 4 bar |

| Machine Dimensions | 45 x 40 x h.120 cm |

| Machine weight | 100 kg |