Project Description

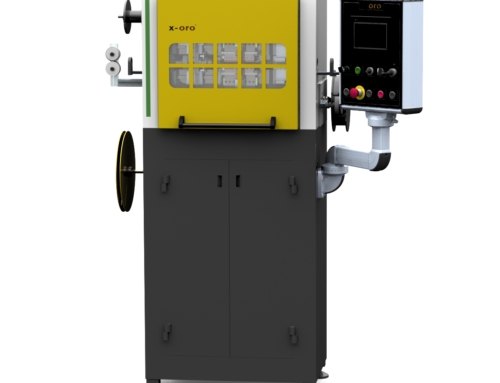

A utomatic machine for the production of rosary chains (in precious as well as non-precious alloys) with smooth balls designed starting from a tube or plate, crimped onto a chain.

utomatic machine for the production of rosary chains (in precious as well as non-precious alloys) with smooth balls designed starting from a tube or plate, crimped onto a chain.

It is also possible to obtain oval, cubic, drop-shaped, barrel-shaped, flat balls, as well as balls/beads with several other shapes on request, including internally any type of chain, that is box chaine, trace/anchor chain, grumetta chain etc., simply by means of the quick change of the tool . The precise position of the single balls/beads can be programmed by means of the touch screen and it is possible to spacing the balls/beads differently from each other, enabling the operator to save/store the programs so as to be subsequently re-used, if necessary.

The machine is equipped with a speed variator / inverter, automatic oil lubrication device as well as control and safety sensors.

Equipment:

PLC (programmable logic controller) unit

5″color touch screen

USB port

Ethernet LAN port

Safety protections

Sensors to detect the end of incoming material

Control sensor to detect outgoing balls/beads

| Ball size | min Ø 1,8 mm max Ø 6 mm |

|---|---|

| Production up to | 30 pcs/min |

| Power Supply | 380 V – 50 Hz |

| Machine Dimensions | 120 x 55 x h.167 cm |

| Net Weight | 370 kg |